An important factor influencing the customer experience is the level of interior noise in a vehicle. The company's image can take a hit if there's any unusual noise. Car Interior Noise Level Comparison Electric cars (EVs) necessitate new noise norms, despite engineers' extensive knowledge of ICE vehicle noise requirements. Many previously inaudible vehicle disruptions are now audible to passengers in EVs due to the lack of a noise-making engine.

How to Test Your Car's Noise Levels at Home

Total background noise.

Automotive publications often use it to compare different vehicle types, making it a valuable metric for benchmarking.

It is a method of evaluating a vehicle's general acoustic comfort and pertains to the overall noise level within the vehicle at its full speed range.

For both soundproofing and speech intelligibility, the Articulation Index (AI) is a reliable metric to employ.

Vehicle engine noise

Vehicle engine noise is one of the most bothersome interior vehicle noises. Road stimulation exacerbates both structure-borne and airborne internal noise.

Subjective assessment, benchmarking, and experience typically form the basis of requirements. We must meet both the decibel level and the frequency balance. We pay special attention to the noise from the tread and tire cavity, which ranges from 200 to 250 Hz.

Read also: Automotive Trends In Customer Demands

The audio set

The audio set has strong ties to the majority of NVH domains. As a first step, you should seal the body as much as you can. Overall, you improve the NVH performance and decrease high-frequency leakage.

To achieve optimal performance at minimal cost and weight, structural damping and heavy-layer isolation mats must be fine-tuned. Strategic placement of acoustic absorption material ultimately enhances the acoustic comfort of the interior.

Noise that is composed of components

The system typically classifies these noises as either system-actuated or client-activated. Customer-actuated sounds, directly linked to actions such as power-operating windows or doors, also provide feedback to the user.

Understanding system-actuated sounds can be challenging due to their independent control by the driver or passengers. When the car is cooling down or heating up, the HVAC system makes a lot of noise and requires a lot of planning.

Vehicle braking

Original equipment manufacturers (OEMs) worldwide are greatly concerned about this noise, which is associated with the chassis. The brake system emits noise due to friction-induced vibrations.

As a result, the automobile owner and anyone else in the vicinity will experience significant annoyance and disruption. The braking noise could result in high warranty costs and low customer satisfaction surveys.

As a result, the automobile industry places a premium on developing brake systems with reduced noise. The issue of brake noise is complex, and research in this field is ongoing.

Furthermore, the elimination of auditory masking from engines in the electrification of vehicles necessitates novel brake designs and heightened attention to noise.

But electric vehicles will use their brakes less often than conventional vehicles. Car Interior Noise Level Comparison In many situations, you won't even need to use the brake pedal to manage the vehicle's speed because the regeneration process that occurs during deceleration charges the batteries. Click here to learn more about electric applications.

Read also: All Wheel Drive Vehicle Comparisons

Three separate stages of evaluation

Using a uniform selection of transducer types and placements allows for efficient execution of multiple tests simultaneously, and developing validated test methods that are fast and easy to implement is good practice.

These techniques should be as general as possible to accommodate different system designs. Engineers should measure themselves and keep up with new notions.

Vehicle, system, and component testing. Car Interior Noise Level Comparison Validations of computer models can either be included in these tests or stand alone. Software engineers employ the tests for a variety of purposes, including development, checking requirements, debugging, and CAE correlations.

Vehicle evaluation

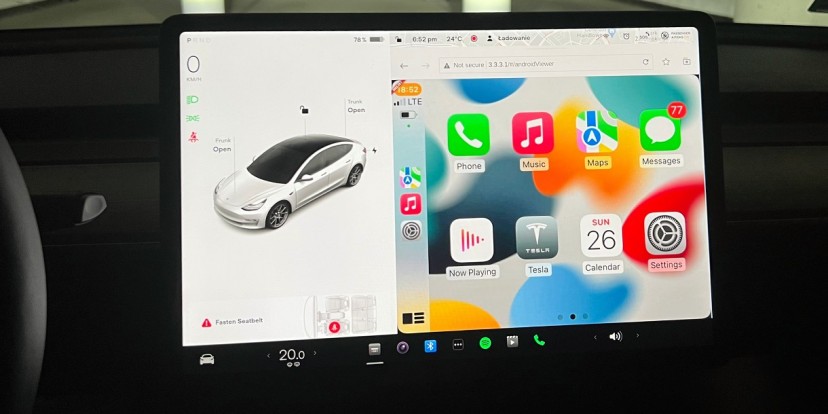

A standard vehicle verification test places the driver's and passengers' ears between two to four microphones mounted at ear level throughout the car. We provide precise details about the test circumstances.

The testing process utilizes a hemi-anechoic test cell, test tracks, an NVH chassis dynamometer, and the NVH laboratory.

During vehicle testing, we test several different types of noise generators:

- We conduct the entire interior noise test on a smooth road test track as the vehicle accelerates from low to high speed. Artificial intelligence (AI) vs. speed and sound pressure level (SPL).

- Specifically designed to measure road noise, the NVH test tracks feature clearly delineated road surfaces, such as smooth, coarse, or grooved. We analyze SPL, narrow band spectra, third octave band spectra, and artificial intelligence at various vehicle speeds. We can measure near-field tire noise using intensity probes with windshields or external microphones.

- The vehicle tests are designed to indirectly test the sound packages at the vehicle level.

- We assess isolated component noise under typical usage settings. We conduct the tests within a moving vehicle using a hemi-anechoic test cell.

- We use microphones at ear level and in the wheelhouse to assess brake noise while driving on a specific test route under various climatic conditions and with all possible brakes.

The system's acoustic transfer function (ATF) is evaluated.

System testing requires a wide variety of acoustic sensors. The NVH lab is the usual place for these kinds of tests, which can be run on the whole vehicle or on individual systems or components.

Here are a few examples of system- and component-level tests:

- We transfer the ATF from the engine compartment to the cabin to inspect the sound system. The Noise Transfer Function (NTF) test measures the structural noise pathways. We conduct these tests on the vehicle using a hemi-anechoic test cell.

- An intensity probe or microphone can be used to quantify the contribution of various surfaces, such as the floor, dashboard, and doors, to background noise. A test track or an NVH chassis dynamometer can be used in a controlled environment, such as a laboratory, to test an entire vehicle. With an acoustic camera, you can also locate leaks and noise sources. Once subsystems, such as a vehicle's front structure or door system, are fitted in an anechoic/reverberation suite, a sound intensity probe is used to assess the contribution from different places. These tests aid in fine-tuning the panel treatment.

- Both absorbed and transmitted sound (STL) are lost. The NVH lab evaluates the sound package's acoustic materials for their characteristics. We test the sound absorption coefficient using a reverberation test cell or an impedance tube. We install the test object in an anechoic/reverberation suite to test the STL. We determine the STL by measuring the sound pressure level (SPL) in the reverberation chamber and the sound intensity in the anechoic chamber, with the reverberation chamber acting as the diffuse sound source.

Test of components

It is necessary to use a wide variety of acoustic sensors while testing components. An NVH laboratory typically conducts these tests on a full vehicle, an individual system, or a single component.

The following elements are included in component noise testing:

- You can use an anechoic or hemi-anechoic test chamber to measure system-level component noise, such as the operation sound of an electric sunroof module or the blower noise of a full HVAC module. While the system operates optimally, the vehicle does not operate within its optimal boundary conditions.

- For instance, you can independently evaluate a small electric motor or solenoid under realistic operating conditions in a hemi-anechoic or anechoic test cell. The component's noise can be detected using SPL (sound power and frequency) or order analysis, depending on the situation.

- A specialized brake squeal dynamometer measures the noise level of the brake system during a complete turn of the vehicle.

Read also: Most Important Car Safety Features

Computer models are validated.

Much of the design work and testing takes place prior to the production of any prototype components or cars. It is important to confirm the body and chassis design early on because they greatly affect the vehicle's NVH performance, particularly with regard to the powertrain and road noise.

In order to link the models, we use measurements taken from real-world vehicles or infrastructure. We frequently use existing cars, enhanced with innovative ideas, as mule cars. Car Interior Noise Level Comparison Modal analysis and transfer function measurements, often known as NTFs and ATFs, are examples of general measures.

Impact hammers, shakers, and sources of volume velocity accomplish excitation. CAE model verification is another use for standardized vehicle verification tests.

FAQ's: Car Interior Noise Level Comparison

How is car cabin noise measured?

Using a microphone or intensity probe, we may determine the relative contributions of various surfaces, such as the floor, dashboard, and doors, to the signal. The use of a test track or an NVH chassis dynamometer in a controlled environment, such as a laboratory, can do this for an entire vehicle.

How to reduce road noise in a car?

- Check the exhaust system and tires.

- Add noise-blocking weather seals.

- Install sound-deadening panels.

- Secure your tools and equipment.

- Add a partition.

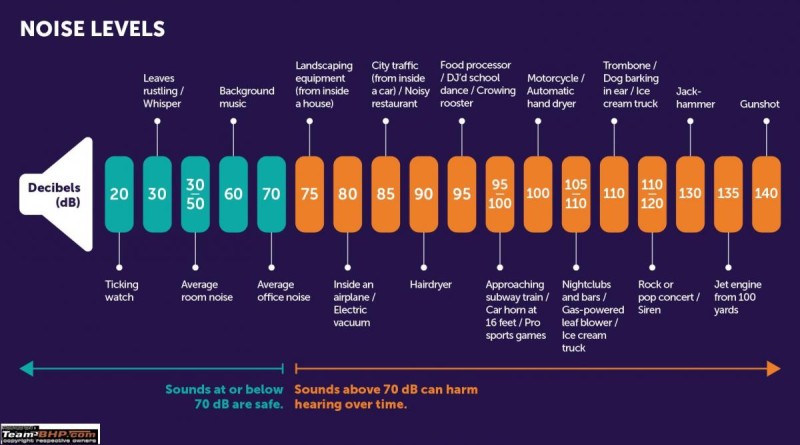

Is 70 dB loud for Tyres?

Tyres with a low decibel level range from 67 to 71 dB. The loudest setting displays audible tones ranging from 72 to 77 dB. There is a noticeable change in decibel level with even a small increase. The amount of outside noise that the tire makes is really doubled for every 3 dB change.

How can I check noise levels?

The gold standard for measuring noise levels is an actual sound level meter, but there are a number of apps for smartphones and tablets that claim to be able to do the job just as well.

.webp)